Maximator Flexdrive

The Flexdrive is a conversion kit developed by Maximator to reduce the air consumption of high pressure compressors.

About 80% of the Maximator applications in the gas industry deal with filling and transferring processes. The compressibility of the gases causes and increasing expenditure of force to generate pressure. This means that the transmission ratio determines the ultimate pressure. With 2 drive parts, only a low drive pressure can be compensated, whereby the greatest possible force is only required later in the process. This is where Flexdrive comes in. It combines the low air consumption at the beginning of the process with the force required at the end.

Benefits Include:

- Compressed air savings of up to 40%

- Time savings of up to 20%

- Simple conversion and retrofitting

Flexdrive ensures overall lower operating costs and shorter process times, thus bringing economic and ecological advantages. There is a very high potential for savings, particularly with large container volumes and low inlet pressures.

What savings potential can be generated?

| Storage Volume | Compressed Air Savings | Filling Time Savings | |

|---|---|---|---|

| Bottle filling from 30 bar to 400 bar target pressure with a DLE 30-75-2 | |||

| 3 litre | 32 % | 22 % | |

| 20 litre | 34 % | 23 % | |

| 50 litre | 36 % | 24 % | |

| Bottle filling from 30 bar to 250 bar target pressure with a DLE 30-2 | |||

| 3 litre | 20 % | 4 % | |

| 20 litre | 22 % | 4 % | |

| 50 litre | 38 % | 4 % | |

| Bottle filling from 30 bar to 250 bar target pressure with a DLE 30-2 | |||

| 120 Litre | 27% | 7 % |

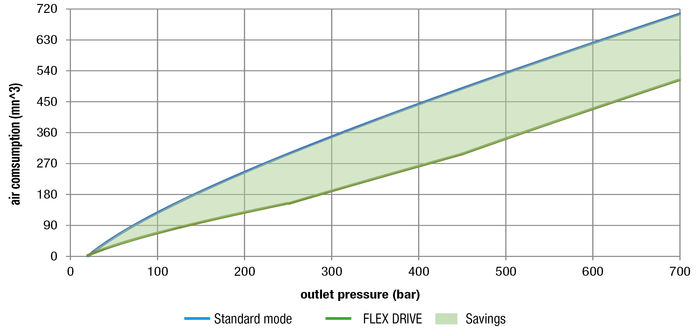

The following diagram shows the savings potential of Flexdrive in terms of outlet pressure and air consumption:

Strengths:

About 80% of the Maximator applications in the gas industry deal with filling and transferring processes. The compressibility of the gases causes an increase expenditure of force to generate pressure. This means that the transmission ratio determines the ultimate pressure. With 2 drive parts, only a low drive pressure can be compensated, whereby the greatest possible force is only required later in the process. This is where Flexdrive comes in. It combines the low air consumption at the beginning of the process with the force required at the end.

- Demand-controlled changeover – pressure-controlled changeover between the transmission ratios

- Automatic switchover – switchover by pneumatic valves

- Can be used in a wide variety of areas thanks to its variants

Applications:

The modification is applicable for all MAXIMATOR gas boosters with 2 air drive sections. The following applications are most common:

- When transferring or filling gaseous fluids into a container, for example a pressurised gas container

- In the supply of internal gas pressure systems

- In the supply of test and control units for compressed air and gases

- In systems for filling airbag gas containers

- At test stands for pressure tests

- Manual – switching style via manual hand valves after reaching stall pressure

- Pneumatic – switching done by pneumatic actuated valves and a pressure switch

- Electric – switching done by solenoid valves, pressure transducer and master PLC

Maximator Flexdrive: Ecologically Effective Efficiency

Maximator Flexdrive: Save 40% on air consumption and boost efficiency. Contact us for more information!