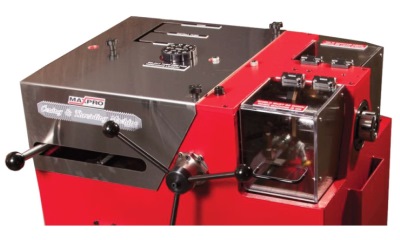

Maxpro Coning and Threading Machine

Maximator Australia is proud to be the distributor of the patented MAXPRO® Technologies Coning and Threading Machine – now able to easily and quickly cone and thread 1-1/2″ medium-pressure tubing.

MAXPRO® has been building patented, state-of-the-art coning and threading machines for seamless, cold-drawn, austenitic stainless steel tubing since 2011. In early 2021, we introduced our newest coning and threading machine capable of handling 1-½” medium-pressure tubing. Model #MTCAT-1.5 Coning & Threading Machine is the first in the industry to offer coning and threading of 1-½” medium-pressure tubing.

MTCAT & MTCAT-1.5 Features

Model #MTCAT and MTCAT-1.5 coning and threading machines are both easy to operate and consistently produce high-quality results. The new MTCAT-1.5 brings these same benefits to the coning and threading of 1-½” outer diameter (OD) medium-pressure tubing. Both coning and threading machines share many quality features including:

Speed

MAXPRO semi-automated machines offer fast and reliable operation, quick set-up times, and improved efficiency. Both machines perform the coning and threading procedures by fixturing the tube once, eliminating extra set-up and downtime between each process. The die head automatically resets after it retracts from threading and is immediately ready for the next tube.

Ease of Use

Both machines use a selector knob to automatically set thread length based on the tubing size. This simplifies the threading process. After brief training for the operator, our machines are ready to use.

Versatility

Both Model #MTCAT and Model MTCAT-1.5 are available in left-hand thread and right-hand thread versions. Pre-bent tubes do not present a challenge as the tube does not rotate during the coning and threading process.

Tool Quality

Both Maxpro coning and threading machines feature hardened blades made from durable, high-quality tool steel. These blades are capable of achieving precise results with a clean surface finish over hundreds of tubes.

Safety

Both machines feature fully enclosed plexiglass shields designed to minimize pinch points and protect the operator from metal chips and oil.

Mess-Free

Our coning and threading machines filter out the cutting oil before returning it to the reservoir and chip collection bucket, minimizing the risk of leaks and spills. It also features a locking lid for mess-free shipping and simple clean-up after production.

- Overall Dimensions 31” W x 19” D x 44” H.

- Available for purchase or hire

| Coning and Threading – MaxPro South

High pressure industries need to conveniently and quickly cone and thread high pressure thick walled stainless steel tubing. Watch our video here!

|

| Changing the Die Head on the Coning and Threading Machine

Instructional video: giving you directions on removing the die head on the coning and threading machine for routine maintenance on the die head. |

| Changing the Tooling on the Coning and Threading Machine

Instructional video: on how to change the die chasers on the Maxpro Coning and Threading machine. Die chasers can be replaced when worn, or if you want to run a different size tubing. |

| Maxpro Technologies Coning and Threading Machine

Efficient, single ended operation makes the Maxpro Technologies Coning and Threading Machine – The New “State of the art” Technology. |