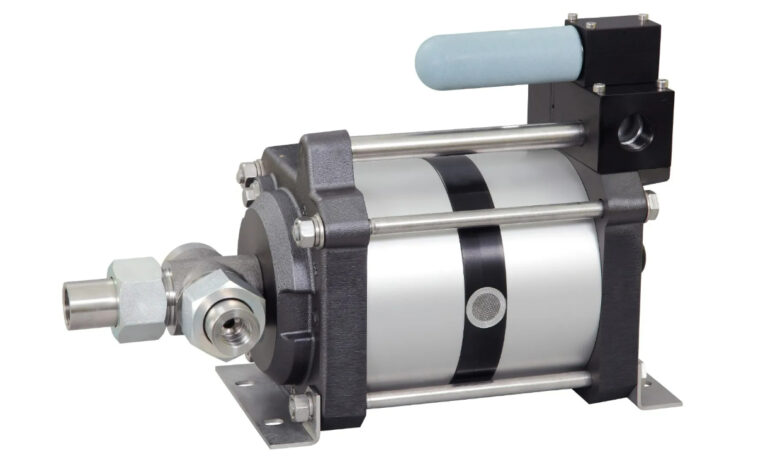

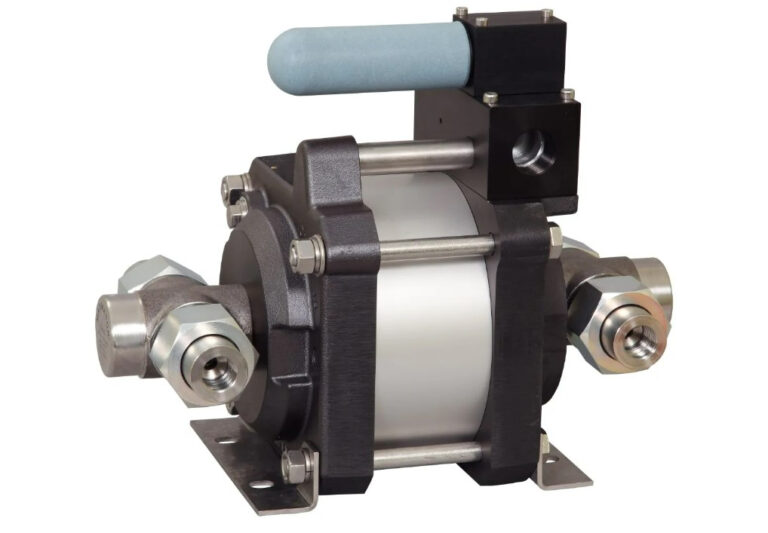

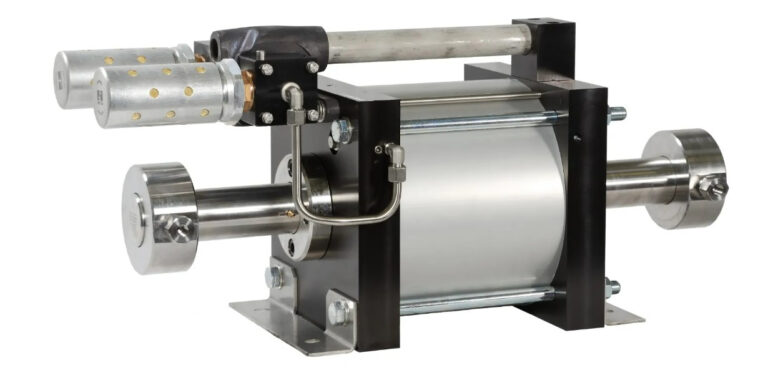

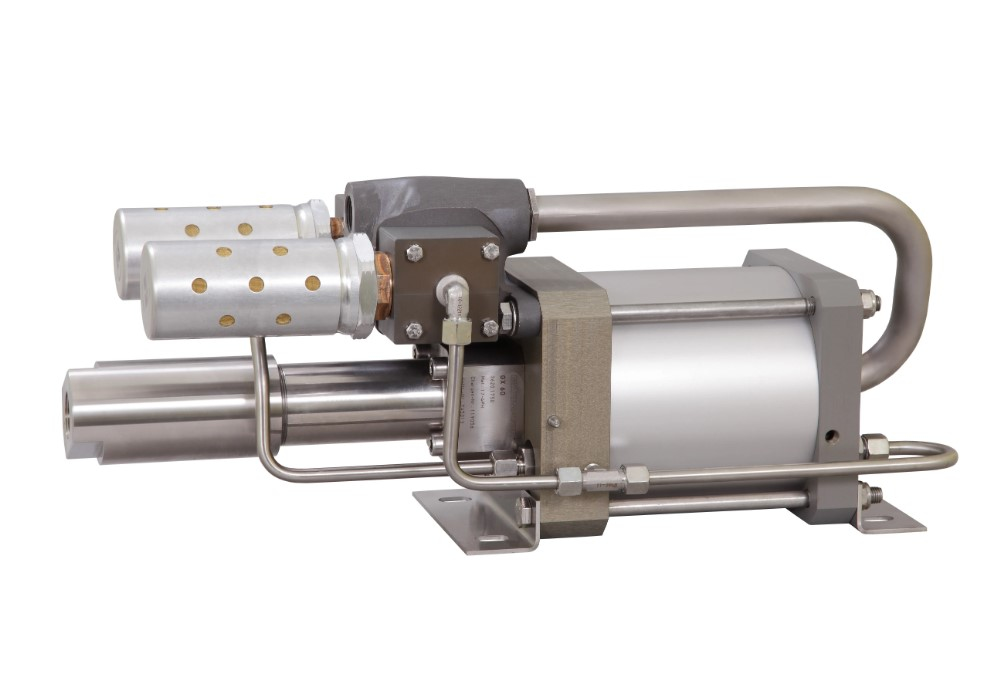

Maximator GX Series High Pressure Chemical Injection Pump

All high-pressure chemical injection pumps from the GX series are suitable for use in zone 1, category 2G/2D IIC TX explosion proof areas (temperature class depending on medium temperature).

GX-Pumps

Pressures to 1,000 bar (14,500 psi)

The GX pumps are distinguished by their high pump capacity. Their robust construction, stainless-steel wetting parts and high resistance to corrosion air drive section make them ideal for the rough operating conditions in the offshore industries.

Examples of application for the GX Series Pumps for the Chemical and offshore industries:

- Injection of inhibitors: such as methanol and glycol in wells

- Injection of coolants

- Aviation and Automotive testing: Brake fluid, skydrol, transmission fluid and power steering fluid

- Pipeline testing

- Charging hydraulic accumulators

- Actuation of subsea valves

GX pumps

- Pressures to 1,000 bar (14,500 psi)

GX pumps are high flow capacity pumps designed for rugged installations and build with environmental resistant materials. They are ideal for offshore applications with stainless steel wetted parts and corrosive resistant external components. All GX series pumps have stainless bodies and plungers, UHMWPE (ultra high molecular weight polyethylene) seals and Viton O-rings as standard.

Options for GX series

- Seal package UHMWPE seals and depending on the fluid

* Viton O-rings as standard: order code: GX35 – V

* NBR O-rings as option: order code: GX35 – N

* EPDM O-rings as option: order code: GX35 – E

* See fluid compatibility guide

- Air control unit for GX series with filter pressure regulator, control pressure gauge and shut-off valve: GX35 with C2

- To protect the pump against excessive outlet pressures, an air safety valve can be fitted to the air control unit: order code: GX with C2/SVair (The outlet pressure has to be indicated.)

- Other options available on request.

P max. = Discharge

** Please note: Click on Pump Type for Technical Data Sheets and Drawings pdf