HULCX

Compressed air driven H2 Compressor.

- Up to 1,050 bar

- Up to 4 kg/h

- Modular System

- Plug and Boost

- Scalable compression power

- Safety and Service Friendly

- -10°C up to +40°C ambient

temperature

Maximator Hydrogen Booster Station – HULC Series

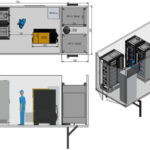

The Maximator HULC Series includes all necessary components to compress Hydrogen or other gases in a safe way to a maximum of 1,050 bar.

Features:

- AIRFLOW PURGE – Innovative purging procedure is replacing the well know N2 flushing and is improving the efficiency of process.

- DESIGN – Designed as an easy changeable 19” rack for maintenance friendly access all connections are installed in the Front of the panel. This design reduces down-time for maintenance, as the complete module can be changed easily in a short time.

- FLEXDRIVE – Specially for filling processes the patent protected FLEXDRIVE solution is increasing the efficiency of the system and is available optionally.

The Power of HYDRO H2ULC

- High Availability

- Innovative Design

- Modular system

- Plug and boost

- Scalable Compression power

A standard configuration up to 1000 bar consists of: one control module (MASTER-module) and up to three gas booster modules (Xmodules)

- First stage module up to 140 bar

- Second stage module up to 400 bar

- Final stage module up to 1000 bar.

This configuration will provide a gas outlet flow of 1 kg Hydrogen per hour. For higher outlet capacities more modules can be connected easily. This complete series is installed in 19“ rack frames with front panel mounting and front connection for easy installation, exchange and access. This system can be easy installed and combined. For all applications the MASTER module is mandatory and is handling safety and functional features for maximum three X-modules. The X-modules can be combined and connected depending on the application.

Areas of application for the HULC

- Filling long-term storage tanks (Home Power Solutions)

- Hydrogen compression for forklift trucks and pilot vehicles such as buses and cars.

- Laboratory applications that require the highest pressures and cost-effective solutions.

- Hydrogen supply for drones.

- Various power to gas applications.

- Hydrogen compression for the supply of project sites that are difficult to access / autonomous energy supply.

- Pressurisation for tests with e.g. forming gas (95% nitrogen and 5% hydrogen)

For more information contact us.

Hydrogen Booster Station options:

Working Pressures:

- 30-90 bar

- 140-300 bar

- 250-600 bar

- 600-1,050 bar

Gas Supply

- 5-90 bar

- 35-300 bar

- 65-300 bar

Cabinet Size:

- Small

- Large

With or without Flexdrive.

What is Flexdrive? Flexdrive is a modification for efficient filling processes. (More information)